Even with perfectly smooth edges, few finished plates will look

exactly like a piece of commercial film. I think this is something to

celebrate. Consummate craftsmanship can still show the hand of the artist.

Contact printing is a way to go. Everything shows, warts

and all. That's part of the attraction of a handcrafted print.

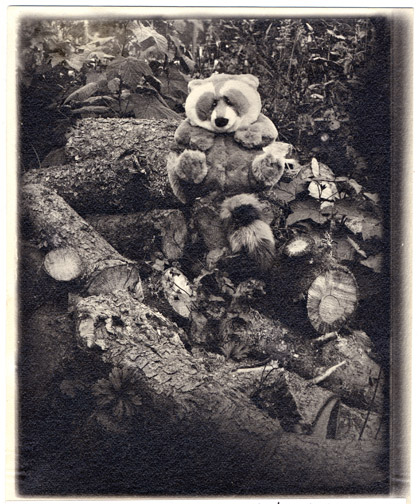

What usually happens with dry plates is a slight emulsion thinning

around all the edges. These thin areas naturally print out

darker, making a natural border around the print, masking for the most

part any flaws around chips.

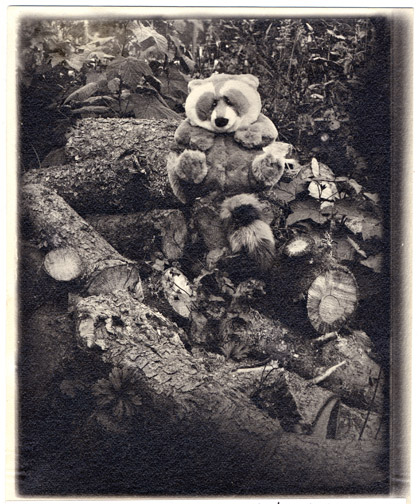

This print is do-it-yourself from start to finish. The dry

plate was contact printed on handmade baryta paper

('Warm ♥ Emulsion'

coated on Rives Lightweight watercolor paper coated with 'TLF Baryta'.

(here).

|

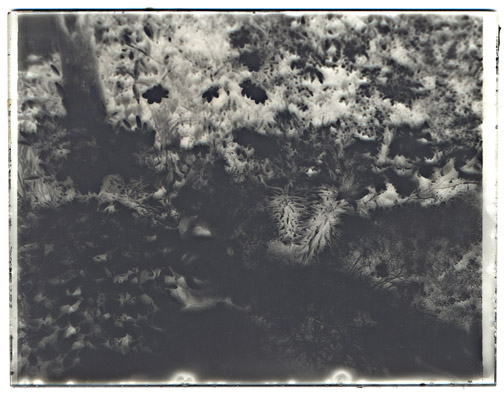

Emulsion has a tendency to pull away from the edges of the plate, even

if the glass is clean. This is rarely a problem. Edge chips

are another matter. Note the bottom edge of this dry plate and

the close-up of one of the chips in the next illustration.

Emulsion has a tendency to pull away from the edges of the plate, even

if the glass is clean. This is rarely a problem. Edge chips

are another matter. Note the bottom edge of this dry plate and

the close-up of one of the chips in the next illustration.

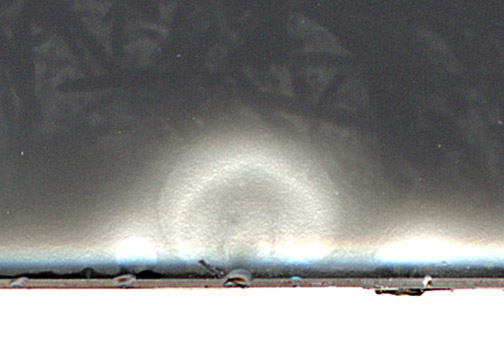

This piece of glass has a raw, snapped edge (left) and a smoothed edge.

A smooth, rounded edge is easy to achieve by hand. An excellent

way is with a set of 3M Diamond Pads in five mesh sizes. Start

with black (120 mesh) and move through all the grits — Red (200),

Yellow (400), White (800) and Blue (1800). The edge will end up

baby butt smooth in only a couple of minutes. You can sand the

plates either wet or dry. Either way, wear vinyl, latex or nitrile

gloves. If you work dry, wear a dust mask.

This piece of glass has a raw, snapped edge (left) and a smoothed edge.

A smooth, rounded edge is easy to achieve by hand. An excellent

way is with a set of 3M Diamond Pads in five mesh sizes. Start

with black (120 mesh) and move through all the grits — Red (200),

Yellow (400), White (800) and Blue (1800). The edge will end up

baby butt smooth in only a couple of minutes. You can sand the

plates either wet or dry. Either way, wear vinyl, latex or nitrile

gloves. If you work dry, wear a dust mask.

The 3M pads are available individually or as a set. Follow the 'Hand Tools' link at the top of

The 3M pads are available individually or as a set. Follow the 'Hand Tools' link at the top of