17. Ammonium Bromide Plain Silver Negative Emulsion, part 2 |

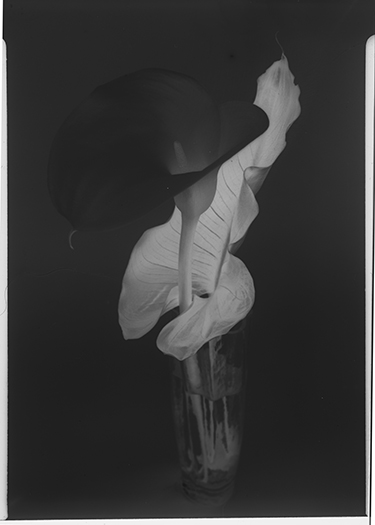

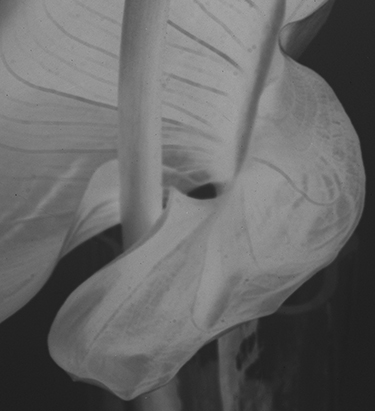

Cala Lily 1 Ammonium Bromide Plain Silver Negative Emulsion, split-bath developed in D23 and borax accelerator (36 g borax/1 liter water);

|

|

|

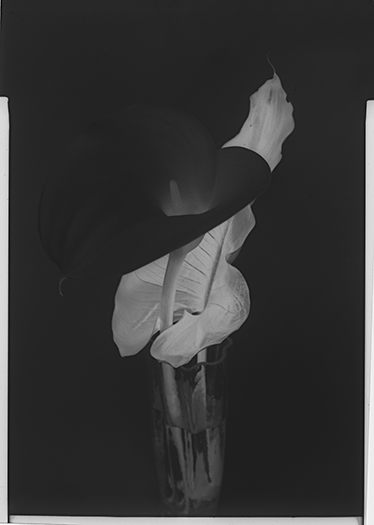

Cala Lily 2 Ammonium Bromide Plain Silver Negative Emulsion, split-bath developed in D23 and sodium carbonate accelerator (9 g sodium carbonate/ 1 liter water)

|

|

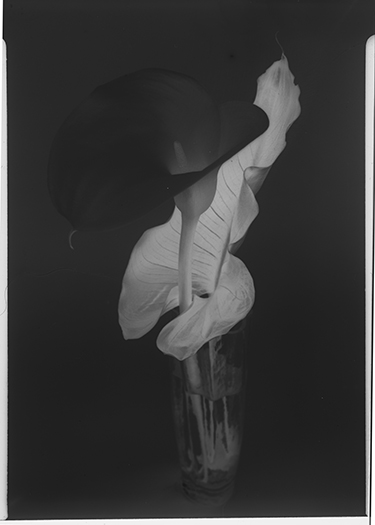

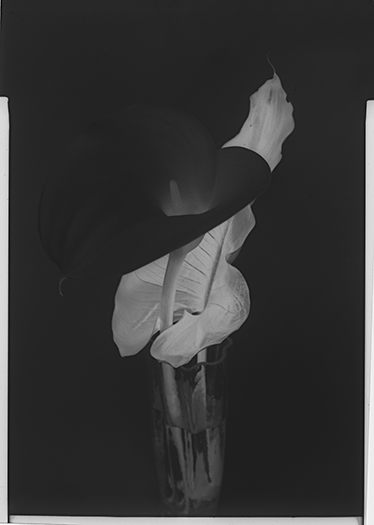

Below is a side-by-side comparison of the same images (borax-accelerated on the left). Although I was playing with composition and lighting, I think you can see the differences you'd expect between a low energy developer and one with a little higher energy. But, there are a lot of variables to play with. Very similar or very different negatives can be made from different developers—depending on how exposure and processing times are handled. Grain is one characteristic that people often have strong opinions about. The crop enlargements in the last set show very clearly the influence of developer energy on grain. There's one important thing to remember when working with sodium carbonate. Don't use an acid stop bath. The residual carbonate could react with the acid to form carbon dioxide bubbles, which will wreck havoc on your emulsion. Think baking soda and vinegar. Instead, use plain water for at least a minute before fixing. TIP: Divide your fix into two trays and give your negative half the total fixing time in each. After a processing session, dispose of the fix in the first tray. Use the second tray as the first tray for your next session and pour a new second tray. If you fix in the first tray until all the white on the negative has cleared, and then give that time again in the second tray, you will always know that a negative is sufficiently fixed. If your clearing time in the first bath starts increasing you know the fixer is close to exhaustion and it's time to dispose of it. Being able to see all this is the great advantage to processing under safelight (a.k.a. "by inspection"). |

|

|

|

|

|

Continued... |

|