|

Notes and Conclusions:

1) 10 drops glyoxal wasn't enough hardener for plain hypo fix.

The print surface developed small bubbles before the end of a sufficient

wash time. Changing to a two-bath fix before washing, making the

second bath a hardening fixer, solved that problem. This is only a

solution, though, if there is no plan to tone the prints. I'll put

15 drops glyoxal in '1B'

(Note: See the next page. Adding more glyoxal did not change

the bubbling problem.)

2) This make didn't employ a syringe and

subsurface silver addition. There is very slight microscopic

peppering, but not enough to support the assertion that subsurface addition

is a necessary technique.

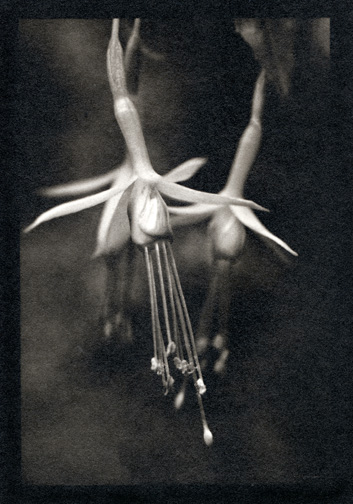

3) The untoned color of the emulsion is a lovely neutral without a

hint of green, influenced, I believe, by the amount of citric acid.

April 4, 2010. Material Info Update -

Fabriano Artistico papers: After a number of months of testing, I am

convinced that Fab Art paper has been changed. I started out with Fab

Art X-white HP paper four years ago and have coated just about every

variety of emulsion imaginable on it. As ugly as some emulsions have

been, one thing I felt confident in saying was that they were

bullet-proof — no bubbling, frilling or lifting. That changed about

four months ago. I started getting tiny bubbles of lifting emulsion

during washing. I originally thought that one of my ingredients had

gone old, but after replacing all of them, one by one, I did a whole

range of paper samples again. With any given run of emulsion, only the

Fabriano Artistico papers develop bubbles. I love Fab Art paper, so I

pushed through for a work-around solution. Bubbles are eliminated, or

at the least greatly reduced if I use hardening fixer and follow with a

'speed wash' protocol (short pre-wash, archival washing aid, shortened

final wash, squeegee, dry).

|