Dry Plate PhotographyPlate Prep and Coating - The Light Farm System |

|

|

November 3, 2011 Updated coating information |

|

Materials required:

|

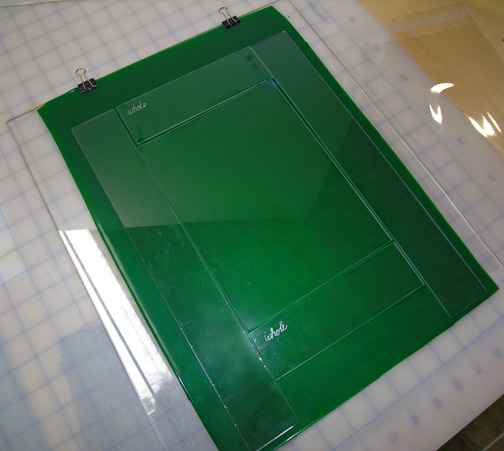

Secure the silicon sheet to the acrylic sheet with the binder clips.

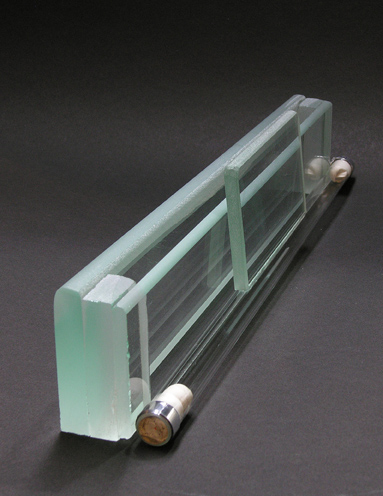

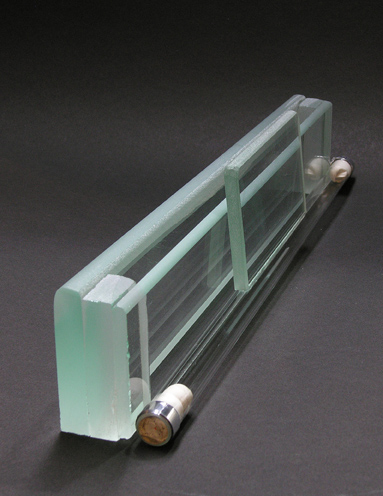

Secure the silicon sheet to the acrylic sheet with the binder clips.Center the plate and arrange the glass guide strips around it, leaving a slight gap. (This allows the emulsion to flow over the edges of the plate and form a nice protective rim of emulsion.) Spritz the glass with a bit of Everclear (don't flood things) and applying a fair amount of pressure, rub the glass. This accomplishes two things: 1) a final cleaning and 2) it forms a good contact between the glass and the silicon. Center the well, emulsion gap at the back, straddling the space between the top guide strip and the plate. Lean the coating rod on the back (gap side) of the well. (Note: In order to show the top space, this illustration has the well set too far up. It should be down just a bit so that you can see the space between the top guide bar and the plate as you look down on the inside the well.) |

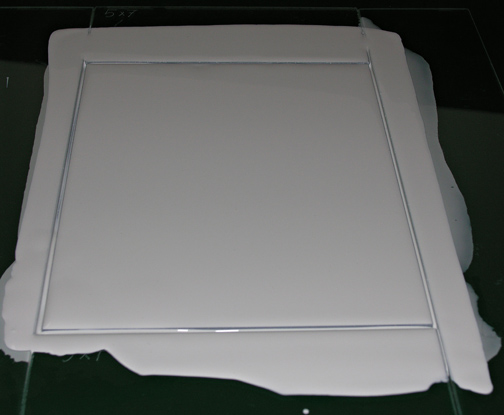

Take the time to do perfect leveling, front-to-back and side-to-side. The first thing I do when I'm preparing to coat is line up the plates. (The set-up shown is for coating 4"x5" plates. It works great to coat two per sheet, side-by-side.) When the emulsion is ready to coat, I take one sheet at a time from the lineup to the coating platform and then carefully return it a few minutes after it's been coated. The plate does its first drying step back in the line-up. Remember: each step between the time you start making the emulsion and you have finished fixing the plate, you must work under safelight (red or deep amber. |

|

Acrylic gesso, diluted with water to the consistency of heavy cream, is an excellent coating practice material. It handles almost identically to emulsion. One note of caution, though. It's messier, by far, than emulsion and harder to clean from the coating tools. Make sure you never let it dry on the well or puddle pusher. The good news, of course, is that you can cheaply practice coating in the light. |

|

|

Replace This Text in js

Replace This Text in js

|

Copyright © The Light Farm |